PU Foam product series

PU Dry Process Composite Board

Product Characteristics:

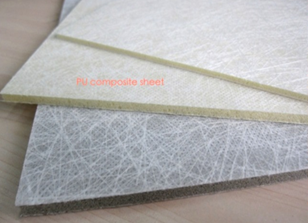

PU dry process composite boards are multi-layer composite sheets made by heat bonding and cool shaping of materials such as chopped glass fiber, non-woven fabric, and polyurethane foam boards using thermoplastic resin. These boards feature light weight, high specific strength, thermal insulation, sound absorption, noise reduction, vibration dampening, high molding efficiency, and good environmental performance. They can be applied to automotive headliners, sunroof sliding covers, picture frame backboards, and other products.

Product Weight:

600-2500g/m²

Dimensions:

Width: Up to 2500mm, Length: Up to 4000mm

Molding Method:

Hot material cold mold pressing

Automotive Manufacturers Using This Product:

SAIC-GM, Dongfeng Nissan, Geely, Citroën, GAC, Hyundai, Kia, etc.

The third-generation ultra-lightweight PU composite board (Ultralight) was successfully developed in 2017.